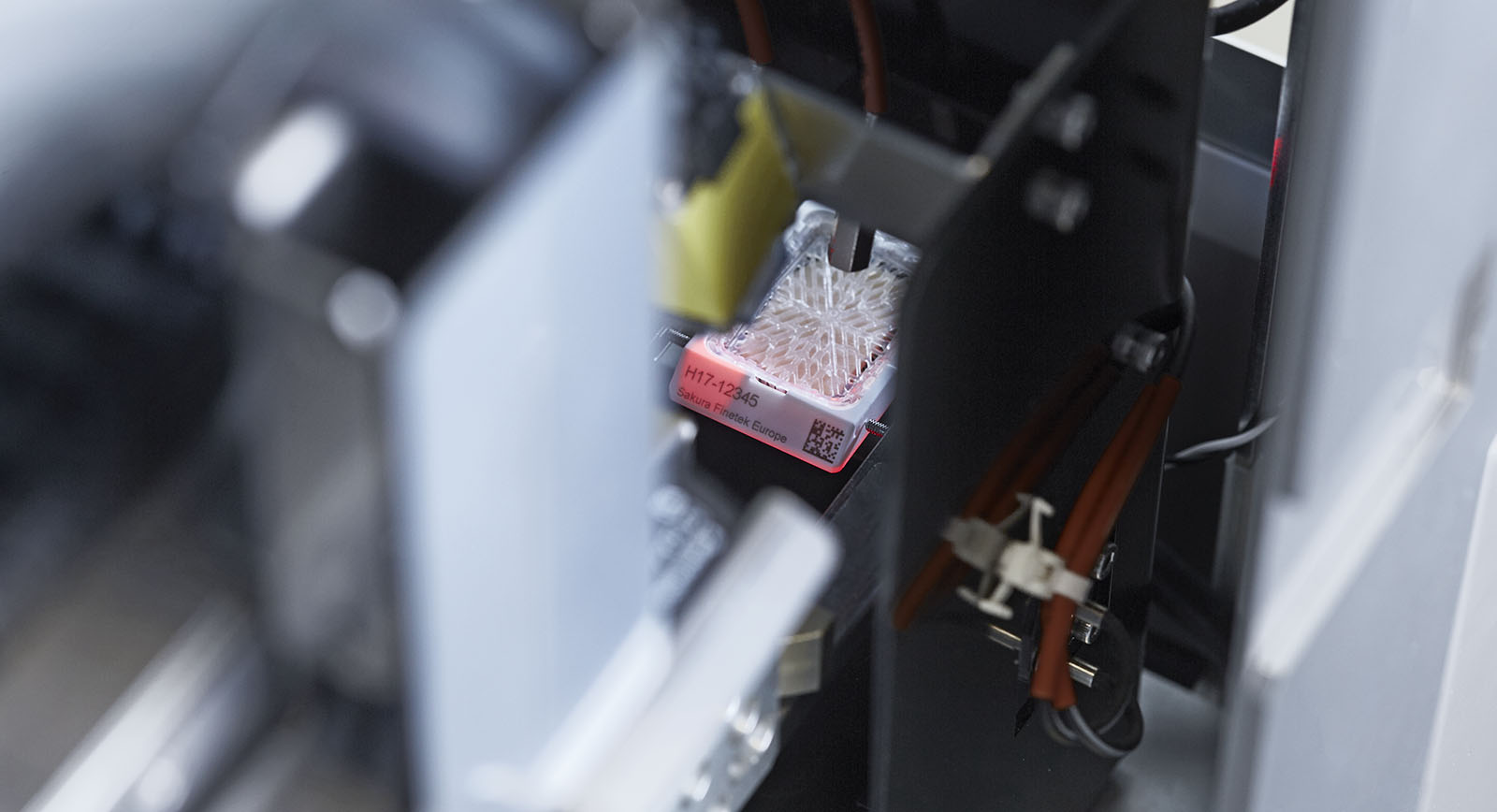

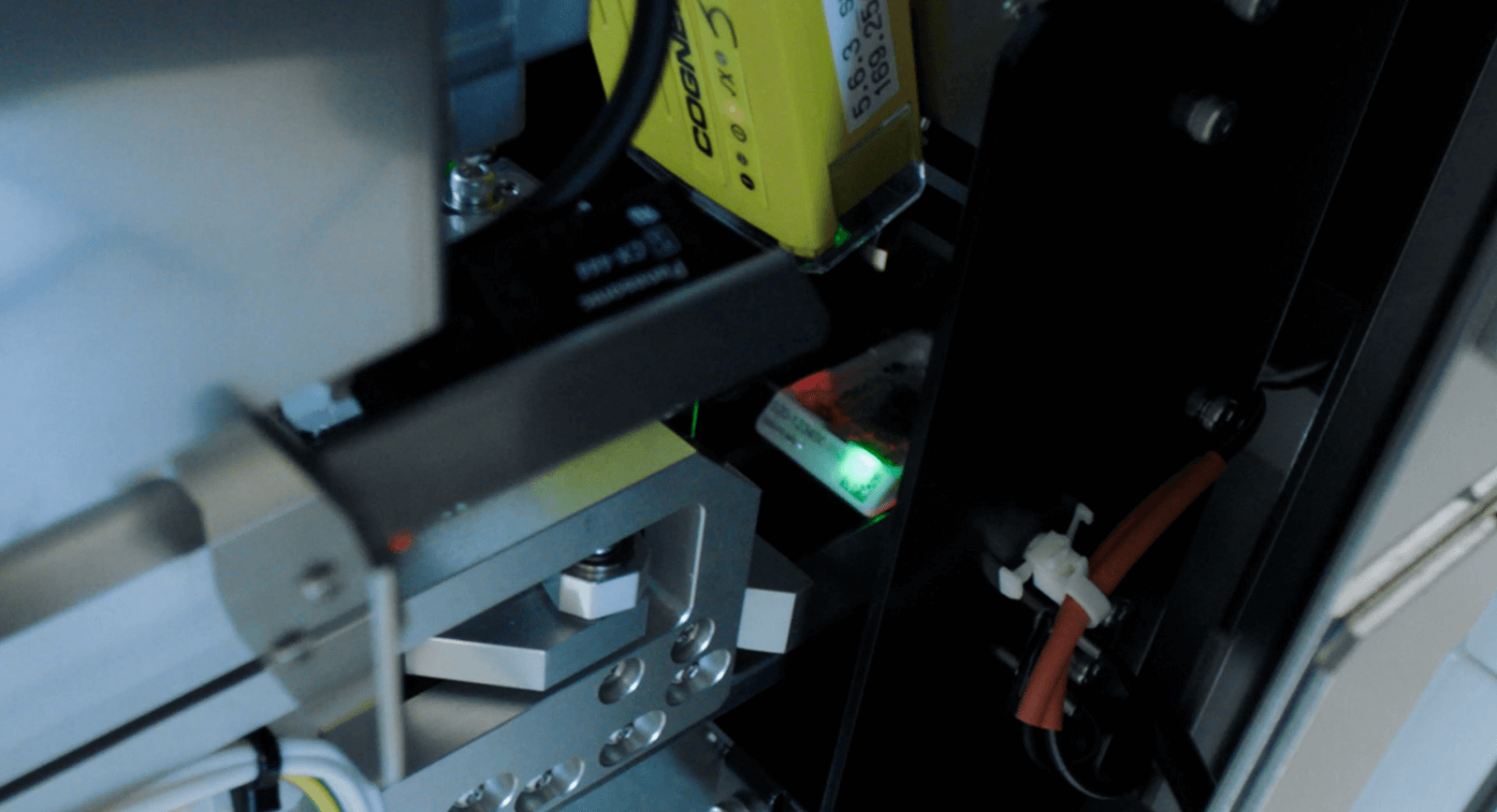

Automated embedding system

Automate tissue embedding with the Tissue-Tek AutoTEC® <i>a120</i>. Improve the productivity of your lab and deliver clean and consistent blocks.

Request infoA supportive automated embedding system

Automation made it possible to free up labour for other purposes.

EMWEB0001-01

We support you to empower patient focus

Our complete range of services supports you in handling your daily challenges to help complete the daily workload, establish shorter turnaround times and improve your lab’s efficiency and quality.

New implementation consultancy service of Sakura Finetek Europe. Bringing new technology into your lab can be a challenge. The biggest challenge is bringing people on board with the change in your lab. We're here to help you. To learn more about Bridge, visit sakura.eu/bridge

Our leasing solution supports your laboratory in benefitting from the latest technology solutions, enabling you to deal with day-to-day challenges without high-capital investments that might be difficult to obtain.

In order to support a smooth daily operation in your lab, it’s crucial that your instruments are reliably operational and continuously available. With a Platinum, Gold or Silver Service Agreement, we empower you to meet your needs and budget. A fixed periodic fee gives you more control of your budget, as costs are then predictable. We take care of your instruments; while you focus on your patients.

Well-trained people can work more efficiently and perform better. That’s why we offer on-site customer training on your instruments to optimise results. We train your staff to acquire in-depth knowledge of the Sakura instruments and consumables, empowering them to use the tools to their fullest potential. (Trainings can be registered to obtain an ISO 15189 standards certificate.)

Maximise your uptime with stock management. Express delivery enables you to order urgently-needed products in small quantities and receive them within one day. (Conditions and exceptions apply. Applicable for consumables and accessories weighing up to 20kg. Hazardous goods will have a longer delivery time.)